Copper production process from ore to cathode

1. Mining

-

Copper ores are extracted from open-pit or underground mines.

-

The most common copper-bearing minerals are chalcopyrite (CuFeS₂), bornite (Cu₅FeS₄), and malachite (Cu₂CO₃(OH)₂).

-

Ore grades are typically low, often less than 1% copper

2. Crushing and Grinding

-

The mined ore is transported to a concentrator.

-

It is crushed and then ground into fine particles to liberate copper minerals from the surrounding rock.

3. Concentration (Flotation)

-

The ground ore undergoes froth flotation.

-

Reagents are added to make copper minerals hydrophobic.

-

Air bubbles carry copper-rich particles to the surface, forming a froth that is skimmed off.

-

The result is copper concentrate, typically containing 20–30% Cu.

4. Smelting

-

Concentrate is dried and fed into a smelter (flash furnace or reverberatory furnace).

-

At high temperatures, sulfides are oxidized, producing matte (a mixture of copper, iron sulfide, and other impurities).

-

Slag (waste material) is removed.

-

The matte usually contains 50–70% Cu.

5. Converting

-

The matte is transferred to a converter furnace.

-

Air or oxygen is blown through to oxidize iron and sulfur.

-

The product is blister copper, about 98–99% pure, with a blistered surface due to escaping sulfur dioxide gas.

6. Fire Refining

-

Blister copper is further refined in a refining furnace.

-

Impurities are removed, producing anode copper (~99% purity).

-

Large copper plates (anodes) are cast for electrorefining

7. Electrorefining

-

Anodes are suspended in tanks containing an acidic copper sulfate solution.

-

A thin sheet of pure copper serves as the cathode.

-

When electric current passes through:

-

Copper dissolves from the anode into solution.

-

Pure copper plates onto the cathode.

-

Impurities either fall off as anode slime (containing precious metals) or remain in solution

-

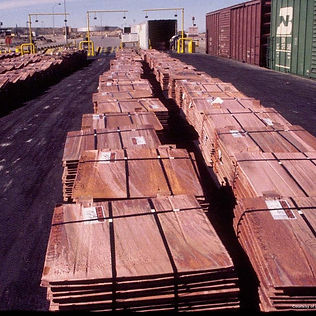

8. Final Product – Copper Cathodes

-

The cathodes are 99.99% pure copper.

-

They are removed, washed, and packaged for sale.

-

Cathodes are the standard form traded globally (LME Grade A copper).

-

They serve as feedstock for wire, rods, tubes, sheets, and alloys.